After-Sales Service Notice for Turkey Region

After-Sales Service Notice for Turkey Region Dear Valued Customers and Partners, We are pleased to inform you that our professional after-sales service team will be deployed in Turkey this week to provide technical support and maintenance services for screen printing machines and related accessories. For our long-term valued customers: Should your equipment require maintenance, troubleshooting, or technical consultation, please feel free to contact us at your earliest convenience. Our team is fully equipped to address your needs promptly and ensure the stable operation of your machinery. For friends with potential future requirements: We warmly welcome you to inquire about our product series, technical specifications, and after-sales support system. We also offer face-to-face consultation appointments—this is an excellent opportunity to discuss customized solutions tailored to your production needs and establish in-depth cooperation. To ensure efficient service arrangement, please reach out to us via the following channels to confirm your needs or schedule an appointment: - Email: fany@lt-xm.com - Phone: +8618965820062 - WeChat/WhatsApp: +8618965820062 We look forward to connecting with you in Turkey and providing you with high-quality, reliable technical support and service experience. Best regards, LINGTIE (XIAMEN)MACHINERY CO.,LTD 2026-1-21

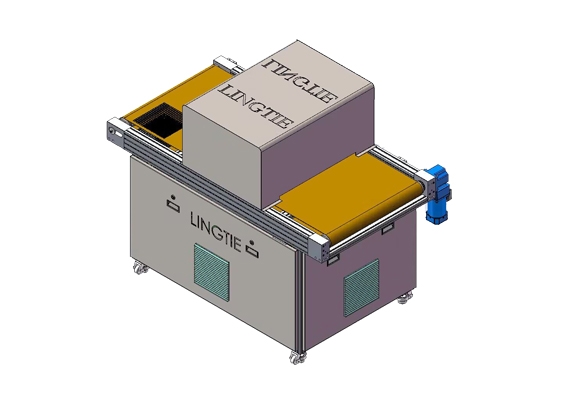

Sécheur UV à LED

Marque:

Lingtienuméro d'article:

LTA- UVprix du marché:

$3000origine du produit:

Chinaport d'expédition:

Xiamen, ChinaDelai:

30 days

La description du dessiccateur UV à LED

- Le système de séchage UV à LED comprend l’unité centrale, l’unité de refroidissement et la lampe UV à LED.

Nous avions encore personnalisé le système de séchage à LED UV (ultraviolet) pour les clients indiens et italiens. (Ils sont nos clients de la machine de sérigraphie rouleau à rouleau).

- L'encre UV doit être utilisée pour l'impression et les autres types d'encres ne seront pas disponibles.

Si l'encre à base de solvant ou d'encre à base d'eau pour laquelle vous êtes utilisé, nous pouvons fournir le sécheur à air chaud (four tunnel).

- IR Dryer est disponible à la vente.

Précédent:

Machine de séchage UV pré-rétractable

-

Machine de séchage UV pré-rétractable

Machine de séchage UV pré-rétractable

La température de Le four de durcissement pré-rétrécissement unique peut atteindre 200 degrés Celsius et comporte plusieurs technologies exclusives pour vos demandes spéciales.

-

Etuve/étuve -LTB-350

Etuve/étuve -LTB-350

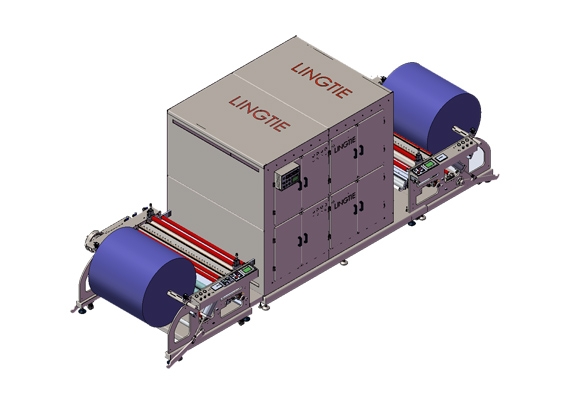

La machine de séchage à air chaud est une partie importante du processus de sérigraphie, elle peut être personnalisée en fonction des besoins réels des utilisateurs de diverses spécifications et fonctions du four (four/boîte de séchage)

-

Séchoir UV pour machine d'impression de feuilles

Séchoir UV pour machine d'impression de feuilles

L'énergie UV « guérit » les encres et les vernis en une fraction de seconde. Un système UV se compose essentiellement des composants suivants : des lampes UV, des réflecteurs, des boîtiers de lampe, un système de refroidissement et un système électronique de commande et de contrôle.

appelle nous : +86-18965820062

appelle nous : +86-18965820062 Messagerie : fany@lt-xm.com

Messagerie : fany@lt-xm.com

français

français English

English Deutsch

Deutsch русский

русский italiano

italiano español

español português

português Nederlands

Nederlands العربية

العربية 한국의

한국의 Türkçe

Türkçe Melayu

Melayu Polski

Polski magyar

magyar ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia Limba română

Limba română 中文

中文

+86-18965820062

+86-18965820062

+8618965820062

+8618965820062